gull lake sandblasting and powdercoating

Gulllake Sandblasting and Powdercoating is your premier provider for sandblasting and powdercoating services throughout the Brainerd Lakes Area and central Minnesota. Our services will help you improve your project or fix an existing one. We have helped thousands of customers in Central Minnesota with their Sandblasting and Powdercoating needs. We are also now a Cerakote Applicator in the Lakes Area and Central MN to customize the look of virtually any item you to bring to us.

At Gulllake Sandblasting and Powdercoating, no project is too big for us, not yet that is. Let us improve that special snowmobile with custom springs or pretty up those old looking rims on your collector's vehicle. Be it a bolt or a stock car frame, we can handle your project with your satisfaction and quick turn around time. We appreciate your time considering our services.

The Perfect way To improve your projects

At Gulllake Sandblasting and Powdercoating, we take pride in customizing your project or fixing what others previously thought looked stunning. Now you just have to choose what service we offer to help you accomplish that. We are the largest facility in Central Minnesota and Brainerd Lakes Area that offers sandblasting, powdercoating, exterior restoration and Cerakote finishing all under one roof. We are proud to serve you, our customer.

1

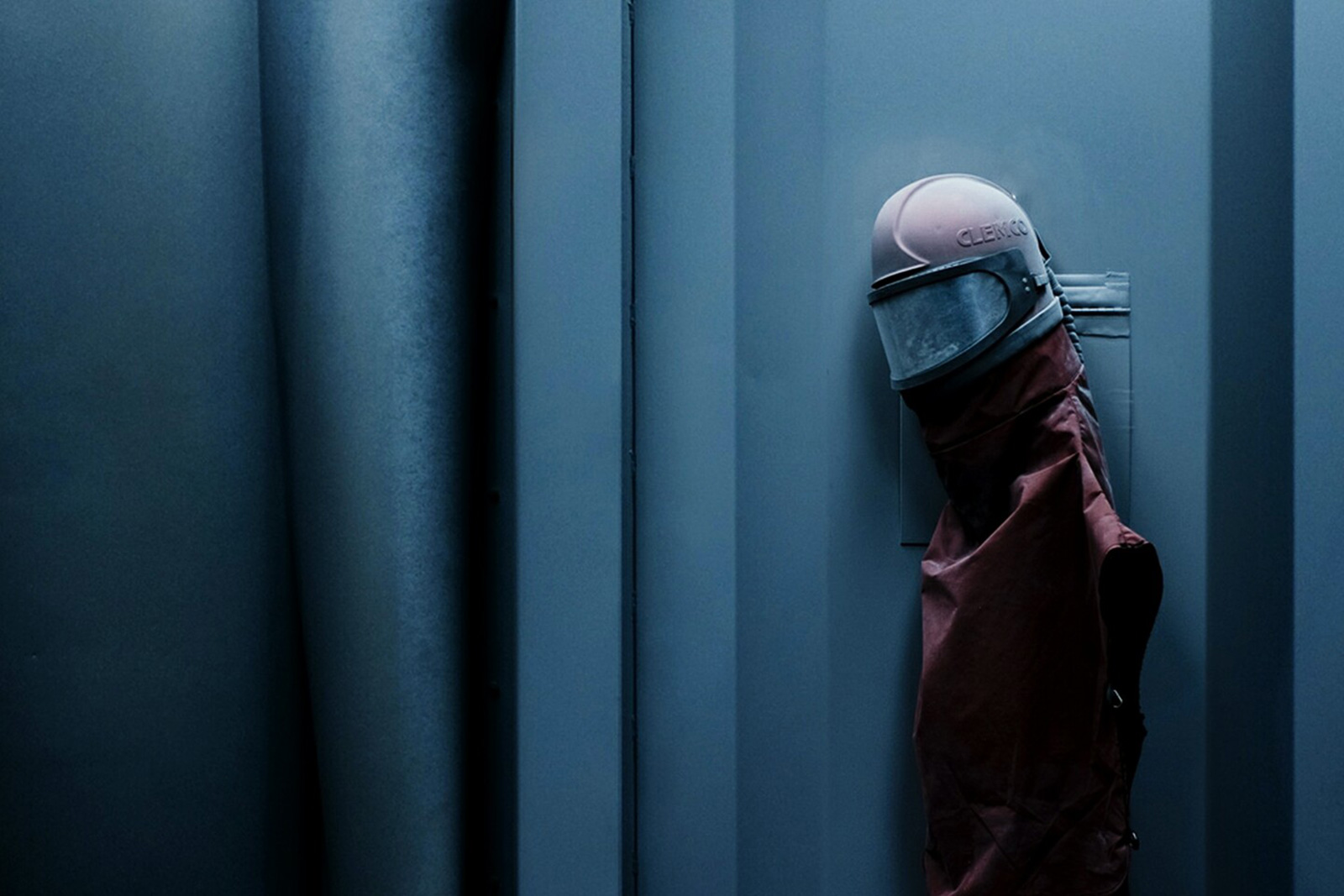

sandblasting

2

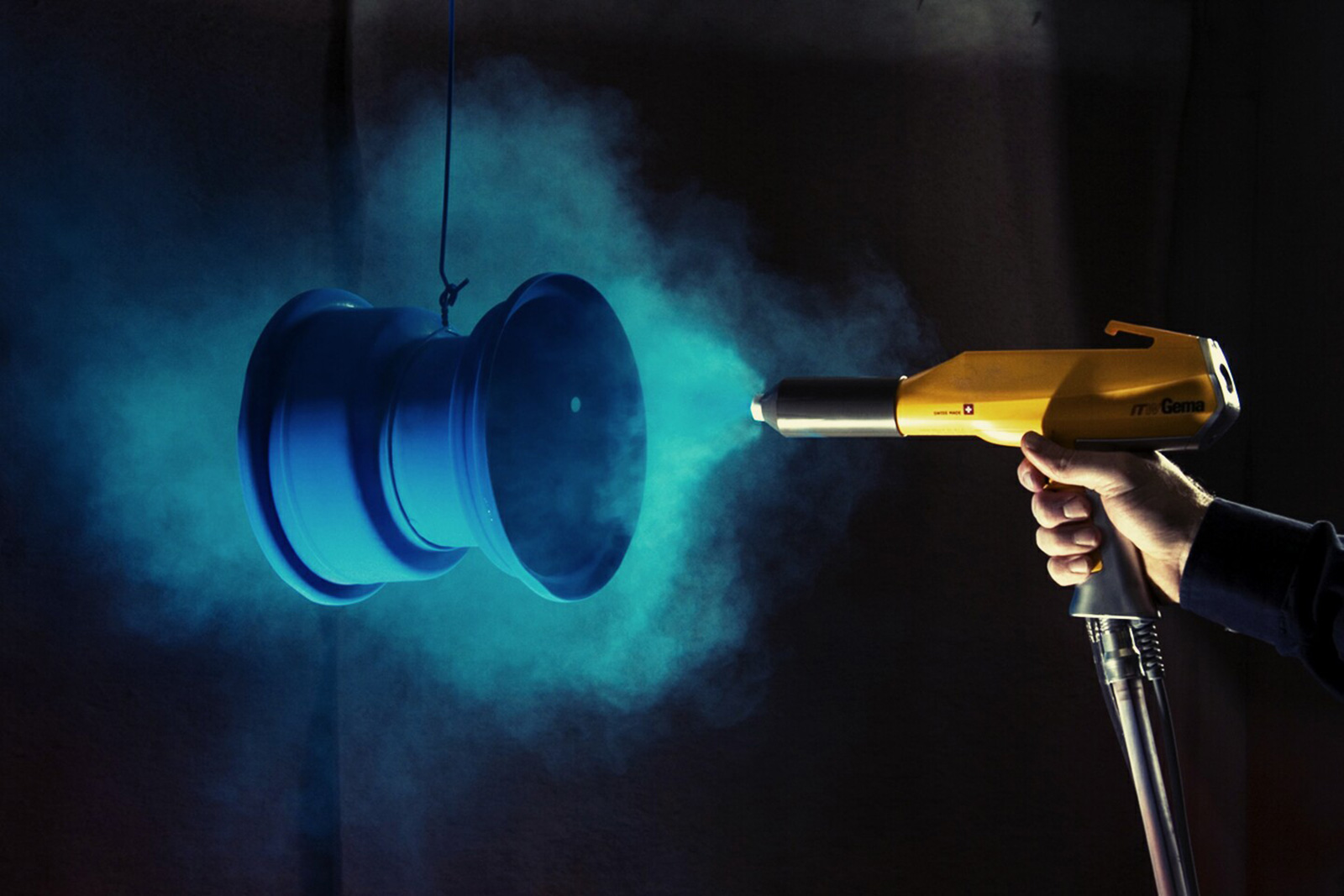

powdercoating

3

cerakote

Support Lakes Proud

shop. buy. support.

Gull Lakes Sandblasting & Powdercoating is your premier provider for sandblasting and powdercoating services throughout the central Minnesota region. We are proud to be a part of the Lakes Proud initiative and hope you continue to buy and use local services. SHOP. BUY. SUPPORT. If we support each other, our region and businesses will thrive. www.lakesproud.com